Galvanized steel strip

Classification :

Keywords:

Galvanized Strip

PRODUCT DESCRIPTION

Galvanized strip steel is a kind of raw material called (zinc), which is used to coat the long and narrow strip steel which is cold-rolled or hot-rolled to varying degrees. Hot dip galvanizing has the advantages of even coating, strong adhesion and long service life. Complex physical and chemical reactions occur between the hot-dip galvanized steel pipe substrate and the molten plating solution, forming a corrosion resistant zinc iron alloy layer with compact structure. The alloy layer is integrated with the pure zinc layer and the strip steel matrix. Therefore, it has strong corrosion resistance.

Use of galvanized strip steel: strip steel is widely used in the production of welded steel pipes, as the blank of cold bending section steel, and in the manufacture of bicycle frames, rims, clamps, washers, spring blades, saw blades, hardware products and blades. The use of high hot dip galvanized strip steel is naturally associated with the application of galvanized strip steel in construction, light industry, automobile, agriculture, animal husbandry, fishery, commerce and other industries.

|

Product name: |

Galvanized Strip |

|

Place of Origin: |

China |

|

Type: |

Steel Strip |

|

Standard: |

AISI, ASTM, BS, DIN, GB, JIS ETC. |

|

Certificate: |

ISO9001 |

|

Grade: |

SPCC,SPCD,SPCE/DC01.DC02.DC03/ST12,Q195 .Etc |

|

Thickness: |

0.11-5.0mm |

|

Surface structure: |

anti-finger print /skin pass/oiled/ dry/chromated |

|

Size: |

Customized according to customer needs |

|

Tolerance: |

±1% |

|

Processing Service: |

Bending, Welding, Decoiling, Cutting, Punching, Welding |

|

Invoicing: |

by actual weight |

|

Delivery Time: |

7-15 days |

|

Technique: |

Hot Rolled Based, Cold Rolled |

|

Port: |

Tianjin Qingdao or according to your requirement |

|

Packaging Details |

in bundles, in bulk, customized packing. |

Production process:

The first stage: pickling and decontamination of the whole roll of strip steel to make the surface bright and clean.

The second stage: after pickling, it is cleaned in ammonium chloride or zinc chloride aqueous solution or mixed ammonium chloride and zinc chloride aqueous solution tank, and then sent to the hot dip tank for galvanizing.

The third stage: after the strip steel is galvanized, it is rolled up and put into storage. The galvanized layer can generally not be less than 500g/m2 according to the customer's needs, and any sample shall not be less than 480g/m2.

Post treatment of galvanized strip steel includes passivation, pre phosphating and oiling. First of all, passivation treatment should be carried out on the galvanized strip steel, which can improve the surface structure and luster of the zinc coating, improve the corrosion resistance and service life of the zinc coating, and improve the adhesion between the coating and the base metal. The chromate passivation treatment is mainly used. Some activators, such as fluoride, phosphoric acid or sulfuric acid, are added to the passivation solution to obtain a thicker chromate film after passivation. When there is fluoride in the passivation solution, the surface tension of the steel strip can be reduced, the film forming reaction can be accelerated, and the chemical polishing effect can be increased to make the passivation film fine and bright.

Warehouse Storage

The company has two highly specialized wide and thick steel plate production lines with trustworthy technology, and has the comprehensive capacity to produce more than 5 million tons of molten steel and more than 3 million tons of steel plates annually. The number of employees reaches more than 10,000. It has steel plate heat treatment technology, extra-thick steel plate production technology, electroslag remelting steel production technology, etc.

Packing and shipping

We can provide: wooden pallet packaging, wooden box packaging, steel strapping packaging, plastic packaging and other packaging methods. We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements.

Transportation method: We can provide container or bulk transportation, road, railway or inland waterway and other land transportation methods for export. Of course, if there are special requirements, we can also use air transportation.

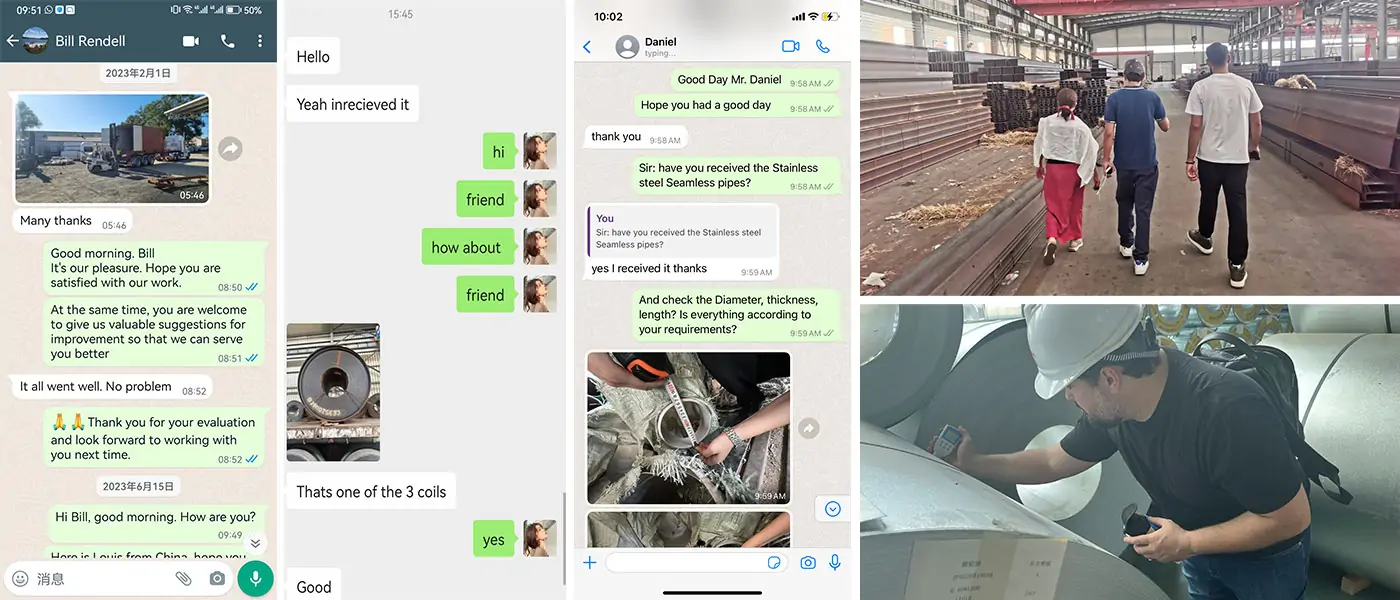

Customer conversation

Wugang has scale advantages, resource advantages, integration advantages, technology research and development advantages, capital operation advantages, and has a complete pre-sales, sales and after-sales service system.Positioned to produce and develop high-end wide and thick plates, we continue to innovate and seek transformation, and are willing to provide global customers with other hot-rolled plates, medium-thick plates, wire rods, cold-rolled plates, galvanized plates, stainless steel and other steel products.

Application field

The products are widely used in water conservancy projects, military equipment, construction industry, aerospace, automobiles, home appliances and other fields.

VIDEO PRESENTATION

Corporate Video5

Corporate Video4

Corporate Video3

Corporate Video2

Corporate Video1

RELATED PRODUCTS

GET A FREE QUOTE